Shared here are some of Glenn Mazur’s lecture series that he taught at various Engineering and Business schools. We value the spread of useful ideas. Please insert the copyright notice as shown in the box below, before using any part of Mazur’s TRIZ materials.

1.0 Introduction to TRIZ

Following World War II, the high quality, technologically advanced products of the United States dominated world markets. With the oil shock of the 1970s, however, many of the economic advantages associated with cheap petroleum were lost and the recovered economies of Europe and Asia emerged as strong competitors in many product areas. The innovative technologies of the US could no longer insulate industries from the customer oriented approaches of European and Asian producers.

The 1990s have seen the recovery of many US industries, most notably the automotive industry. This has been due in part to the influence of many Japanese quality methodologies introduced here by the late Dr. Kaoru Ishikawa, Dr. Masao Kogure, Dr. Yoji Akao, Dr. Noriaki Kano, Mr. Masaaki Imai, and many others. These quality methods have helped US industries reduce defects, improve quality, lower costs, and become more customer focused. As the quality gap with countries like Japan gets smaller, the US is looking for new approaches to assure customer satisfaction, reduce costs, and bring products to the market faster. In the US, we say "better, cheaper, faster."

While there are many widely used design and development approaches such as Quality Function Deployment, these show us what to solve but not always how to solve the technology bottlenecks that arise. One technique, the Reviewed Dendrogram, relies on the experience of designers which may be limited to certain areas of expertise such as chemistry or electronics. Thus, a solution that might be simpler and cheaper using magnetism could be missed. For example, a materials engineer searching for a dampener may limit his search to rubber based materials. A more efficient solution might lie in creating a magnetic field. Since this is outside the experience of the engineer, how could he imagine such a solution? Using TRIZ, he would be able to explore design solutions in fields other than his own.

Rockwell International's Automotive Division faced a problem like this. They were losing a competitive battle with a Japanese company over the design of brakes for a golf cart. Since both Rockwell and the Japanese competitor were in the automotive field, they were competing on redesigns of an automobile brake system but with smaller components. In TRIZ, this seeking solutions only in one's field is called "psychological inertia" because it is natural for people to rely on their own experience and not think outside their specialty. With TRIZ, the problem was solved by redesigning a bicycle brake system with larger components. The result was a part reduction from twelve to four parts and a cost savings of 50%.

2.0 The History of TRIZ

There are two groups of problems people face: those with generally known solutions and those with unknown solutions. Those with known solutions can usually be solved by information found in books, technical journals, or with subject matter experts. These solutions follow the general pattern of problem solving shown in figure 1. Here, the particular problem is elevated to a standard problem of a similar or analogous nature. A standard solution is known and from that standard solution comes a particular solution to the problem. For example, in designing a rotating cutting machine(my problem), a powerful but low 100 rpm motor is required. Since most AC motors are high rpm (3600 rpm), the analogous standard problem is how to reduce the speed of the motor. The analogous standard solution is a gear box or transmission. Then, a gear box can be designed with appropriate dimensions, weight, rpm, torque, etc. can be designed for my cutting needs.

Fig. 1 General Problem Solving Model

2.1 Inventive Problems

The other type of problem is one with no known solution. It is called an inventive problem and may contain contradictory requirements. As long ago as the 4th century, an Egyptian scientist named Papp suggested there should be a science called heuristics to solve inventive problems. In modern times, inventive problem solving has fallen into the field of psychology where the links between the brain and insight and innovation are studied. Methods such as brainstorming and trial-and-error are commonly suggested. Depending on the complexity of the problem, the number of trials will vary. If the solution lies within one's experience or field, such as mechanical engineering, than the number of trials will be fewer. If the solution is not forthcoming, then the inventor must look beyond his experience and knowledge to new fields such as chemistry or electronics. Then the number of trials will grow large depending on how well the inventor can master psychological tools like brainstorming, intuition, and creativity. A further problem is that psychological tools like experience and intuition are difficult to transfer to other people in the organization.

This leads to what is called psychological inertia, where the solutions being considered are within one's own experience and do not look at alternative technologies to develop new concepts. This is shown by the psychological inertia vector in figure 2.

Fig2. Limiting Effects of Psychological Inertia

When we overlay the limiting effects of psychological inertia on a solution map covering broad scientific and technological disciplines, we find that the ideal solution may lie outside the inventor's field of expertise. This is seen in figure 3 where the ideal solution is electromechanical but is outside the experience of the mechanical engineer and so remains untried and may even be invisible. If problem solving was a random process, then we would expect solutions to occur randomly across the solution space. Psychological inertia defeats randomness and leads to looking only where there is personal experience.

Figure 3. Ideal Solution May Be Outside Your Field.

2.2 Genrich S. Altshuller, the Father of TRIZ (Theory of Inventive Problem Solving)

A better approach, relying not on psychology but on technology was developed by Genrich S. Altshuller, born in the former Soviet Union in 1926. His first invention, for scuba diving, was when he was only 14 years old. His hobby led him to pursue a career as a mechanical engineer. Serving in the Soviet Navy as a patent expert in the 1940s, his job was to help inventors apply for patents. He found, however, that often he was asked to assist in solving problems as well. His curiosity about problem solving led him to search for standard methods. What he found were the psychological tools that did not meet the rigors of inventing in the 20th century. At a minimum, Altshuller felt a theory of invention should satisfy the following conditions:

be a systematic, step-by-step procedure

be a guide through a broad solution space to direct to the ideal solution

be repeatable and reliable and not dependent on psychological tools

be able to access the body of inventive knowledge

be able to add to the body of inventive knowledge

be familiar enough to inventors by following the general approach to problem solving in figure 1.

In the next few years, Altshuller screened over 200,000 patents looking for inventive problems and how they were solved. Of these (over 1,500,000 patents have now been screened), only 40,000 had somewhat inventive solutions; the rest were straight forward improvements. Altshuller more clearly defined an inventive problem as one in which the solution causes another problem to appear, such as increasing the strength of a metal plate causing its weight to get heavier. Usually, inventors must resort to a trade-off and compromise between the features and thus do not achieve an ideal solution. In his study of patents, Altshuller found that many described a solution that eliminated or resolved the contradiction and required no trade-off.

Altshuller categorized these patents in a novel way. Instead of classifying them by industry, such as automotive, aerospace, etc., he removed the subject matter to uncover the problem solving process. He found that often the same problems had been solved over and over again using one of only forty fundamental inventive principles. If only later inventors had knowledge of the work of earlier ones, solutions could have been discovered more quickly and efficiently.

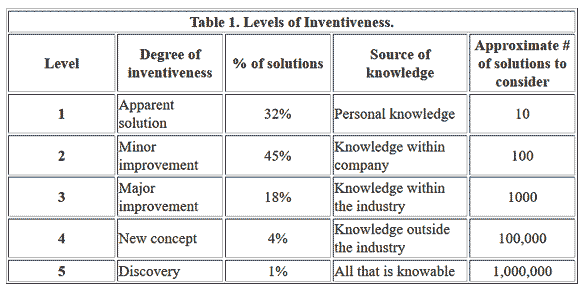

In the 1960s and 1970s, he categorized the solutions into five levels.

Level one. Routine design problems solved by methods well known within the specialty. No invention needed. About 32% of the solutions fell into this level.

Level two. Minor improvements to an existing system, by methods known within the industry. Usually with some compromise. About 45% of the solutions fell into this level.

Level three. Fundamental improvement to an existing system, by methods known outside the industry. Contradictions resolved. About 18% of the solutions fell into this category.

Level four. A new generation that uses a new principle to perform the primary functions of the system. Solution found more in science than in technology. About 4% of the solutions fell into this category.

Level five. A rare scientific discovery or pioneering invention of essentially a new system. About 1% of the solutions fell into this category.

He also noted that with each succeeding level, the source of the solution required broader knowledge and more solutions to consider before an ideal one could be found. His findings are summarized in Table 1.

Table 1.

What Altshuller tabulated was that over 90% of the problems engineers faced had been solved somewhere before. If engineers could follow a path to an ideal solution, starting with the lowest level, their personal knowledge and experience, and working their way to higher levels, most of the solutions could be derived from knowledge already present in the company, industry, or in another industry.

For example, a problem in using artificial diamonds for tool making is the existence of invisible fractures. Traditional diamond cutting methods often resulted in new fractures which did not show up until the diamond was in use. What was needed was a way to split the diamond crystals along their natural fractures without causing additional damage. A method used in food canning to split green peppers and remove the seeds was used. In this process, peppers are placed in a hermetic chamber to which air pressure is increased to 8 atmospheres. The peppers shrink and fracture at the stem. Then the pressure is rapidly dropped causing the peppers to burst at the weakest point and the seed pod to be ejected. A similar technique applied to diamond cutting resulted in the crystals splitting along their natural fracture lines with no additional damage.

Altshuller distilled the problems, contradictions, and solutions in these patents into a theory of inventive problem solving which he named TRIZ.