The ISO 16355-7 standard for digitalized products and services has just been approved for the next draft stage and final publication is planned for later in 2022.* There is a great urgency to this standard as the role of software and information systems has dramatically changed the way traditional products and services are designed, produced, and operated. Several recent news articles have succinctly captured this new era.

For example, John Seabrook writes about the new Ford F-150 Lightening truck in his January 24 2022 New Yorker article “America’s Favorite Pickup Truck Goes Electric.” During his tour of the Rouge assembly plant, Ford’s CEO, Jim Farley, explained:

“This industry is overly focused on the propulsion change. But the real change is that we are moving to a software-defined experience for our customers.”

Comparing electric vehicles to the mobile phone industry, Farley continued:

“the most important thing was that the software decided what kind of hardware got put on those machine.”

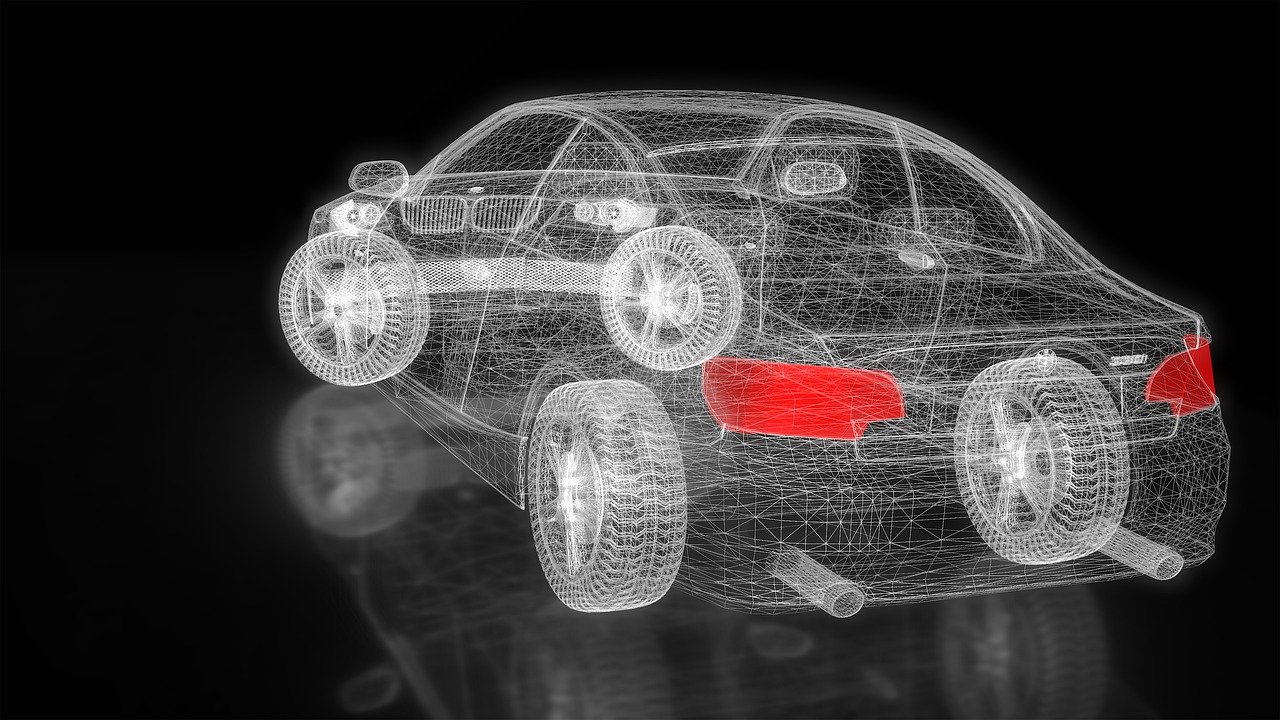

The gist of the article from a QFD perspective is that hardware will be designed in the future to support the software, and not the other way around. Keith Naughton discusses Ford’s electric vehicle software development in his February 3 2022 Bloomberg article “Ford Reengineers Plug-In Mustang In Real Time to Boost Profit.” Keith cites Farley’s “on-the-fly” engineering approach:

“Ford will no longer wait for the next model change to rework a vehicle. With software updates and hardware reengineering, the company is lowering the cost to build the Mach-E at its factory in Mexico in real time.”

Like other software-intensive products, these vehicles may come in “versions” where design changes are released on an ongoing basis, affecting the entire supply chain for components and the entire value chain for after sales support and service/maintenance.

The impact of maintenance and repair was also in the news in Aarian Marshall’s February 3 2022 Wired article “A fight over the right to repair cars turns ugly.” In recent years, the right to access proprietary software operating systems on mechanical products like automobiles, agricultural implements, and others by product owners and non-dealer service technicians has been contentious. Right-to-repair laws are being enacted to assure that data access ports, diagnostic codes, manuals and the like are made available to independent mechanics.

However, as software updates are now being made wirelessly, there is concern that the current right to repair laws are inadequate to assure access to independent mechanics. The data streams that are produced contain much data about driving habits, locations, and other personal information, that while may be anonymized for legitimate uses, could be vulnerable to hacking and even hijacking.

For QFD practitioners, the ramifications of this information revolution present opportunities for us to improve our methods. Here are a few.

1. "The change from software supporting hardware to hardware supporting software is a new business model. Hoshin Kanri or Policy Deployment will be useful here. Hoshin is a powerful approach to investigating, initiating, involving, and managing a new business model. It helps set measurable inputs and outputs to effect the change, identify roles and responsibilities, set time frames, and employ continuous improvement. Hoshin Kanri is an advanced topic in the QFD Black Belt® course and is described in ISO 16355-2:2017.

2. The software-hardware relationship is managed using technology deployment. The gateway to technology deployment, cost deployment, reliability deployment, and others in both Modern Blitz QFD® and Comprehensive QFD is through function deployment. What precedes function deployment is Voice of Customer and quality deployment. Some key points:

Voice of Customer must be translated into product-independent customer needs. This process has specific steps and tools which are taught in the QFD Green Belt® training, and with advanced tools in the QFD Black Belt® training. Some are described in ISO 16355-3:2019 and ISO 16355-4:2017.

Customer needs interface with quality deployment through functional requirements in the maximum value table and house of quality which are taught in the QFD Green Belt® and with advanced tools in the QFD Black Belt® trainings and are described in ISO 16355-5:2017. The design freedom to change the software-hardware relationship is protected only when the functional requirements are technology and component independent/agnostic. The “roof” on the house of quality (HoQ) matrix should be avoided at this time.

Cross-functional teams should include both hardware and software developers. QFD methods and tools for hardware, software, and service are taught in the QFD Black Belt® training.

3. Hackers and abusers should be considered “customers.” This novel approach is being worked on by three QFD experts** who are currently driving a Voice of Customer Think Tank at the International Academy for Quality. They have included hackers and abusers in our VOC list in order to anticipate the “benefits” they seek when breaking software, in order to harden defenses.

QFD for software applications goes back to the early 1990s where the focus was on software applications such as databases, word processing, and the like. The QFD Institute Belt training courses have included it for decades with the focus being on software to support/replace physical products and human activities. As we see more applications of QFD on these new software-hardware systems, we are updating our training accordingly. The QFD Green Belt® Update and QFD Black Belt® Update courses will include these updates as they are developed.

……………………………………….

* ISO 16355-7 standard for digitalized products and services --- Kudos to the extraordinary efforts of Sixten Schockert and Georg Herzwurm of Germany and Kim Stansfield of the UK who have made lightening progress (at least by ISO timing). So many thanks to them.

** Hackers and abusers should be considered “customers.” -- The novel VOC approach for digitalized products by three QFD experts -- Catherine Chan of Hong Kong and Kim Stansfield of the U.K. (both QFD Black Belts®), together with Glenn Mazur, QFD Red Belt®.